What is injection molding machine?

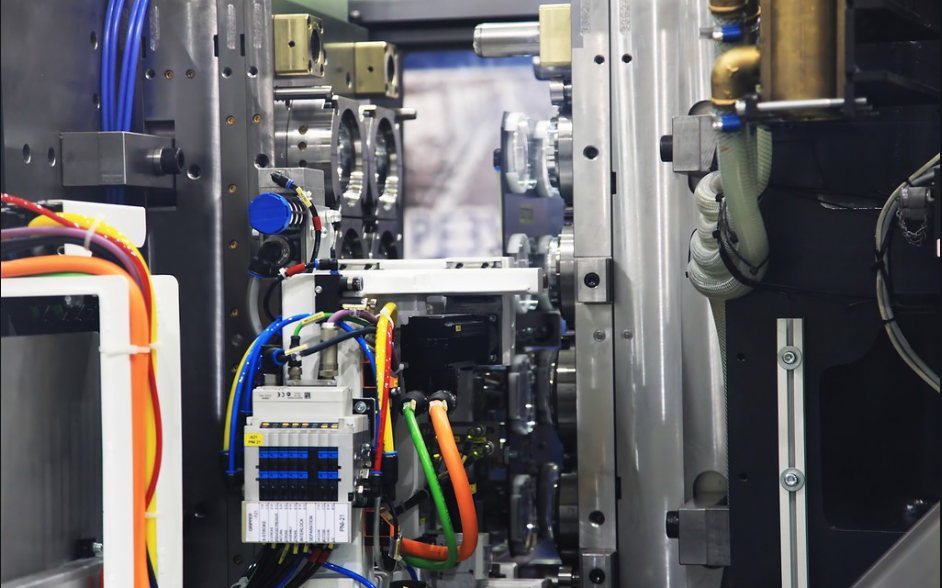

An injection molding machine is comprised of four main components: the base, the hopper, the barrel, and the clamping unit. There are also smaller components such as the nozzle, ejector pins, split mold, clamping unit, injection unit and hydraulic unit.The base holds all the other parts and the electronics needed to run the machine. The electronics on the device have to control a range of heaters, hydraulics, sensors, and injection pressure.

What is injection molding process?

Injection molding is a method to obtain molded products by injecting plastic materials molten by heat into a mold, and then cooling and solidifying them.

The method is suitable for the mass production of products with complicated shapes, and takes a large part in the area of plastic processing.

The process of injection molding by this machine is divided into 6 major steps as shown below.products can be made successively by repeating the cycle.

1. Clamping

2. Injection

3. Dwelling

4. Cooling

5. Mold opening

6. Removal of products

This injection molding method is ubiquitous in products in life, such as electronic products, medical products, household products, household appliances, etc.Mass products are made repeatedly through this method, which greatly improves production efficiency and saves labor costs, and people can do a lot of their private customization by injection molding. Any a molding sample can be do 3D drawing design and make it truth.

Post time: Mar-02-2023