Customized Electronic Plastic Parts Mold injection Process Factory

Customized injection plastic parts mold factory in china

|

Name

|

Custom Plastic injection parts

|

|

mould material

|

45#,P20,H13,718,2738,NAK80,S136,etc.

|

|

mould base

|

LKM,HASCO,etc or as per Customer's Requirment.

|

|

Cavity

|

1 or more

|

|

Runner

|

cold runner or hot runner

|

|

Mould life

|

45# :300,000-500,000shots

|

|

P20: 500,000shots

|

|

|

718: 700,000shots

|

|

|

Design software

|

UG,PROE,CADetc.

|

|

Plastic material

|

PP,PC,PE,ABS,PS,PVC,PET,PA6/66,etc.

|

|

Delivery time

|

20-35days

|

|

Process

|

We will offer a detailed production schedule and send weekly reports with digital pictures

and videos which show the machining progress |

1. Experience

Since the company was established in 2012, we have more than 10 years of experience in the field of plastic injection mold and injection parts.

2.Design Ability

We have an excellent Design Team,We listen voice from our clients and give them good advice to make sure the production more economic and efficient, also makes the product more functional.

3.Good Communication

Communication is one of the most important factors in our cooperation. Our sales and engineers can best grasp the demands of customers, understand their intentions, and provide the best products to them.

4.Quality Control

Our quality control includes IQC(incoming quality control), PQC(production quality control) and FQC(final quality control). With QC report for every batch of production, all production data is recoreded in our ERP system.

5.Fast delivery

We do plan and time table for projects, so it’s no need to worry about delivery, also We have ability to handle urgent orders.

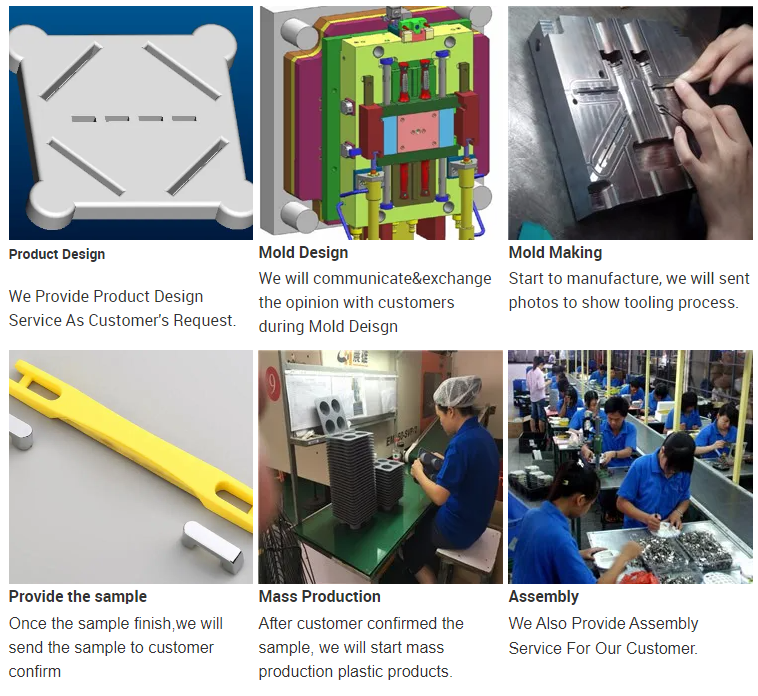

One Stop Service from mold make to products assemble

Mold Process

RFQ:

Q1.When can I get the price?

A :We usually quote within 24 hours after we get your inquiry. If it is very urgent, please call us or tell us in your email so

that we will regard your inquiry as priority.

Q2.How long is the lead time for mold?

A :It depends on the mold’s size and complexity. Normally, the lead time is 25-35 days. If the molds are very simple and not in big size, we can work out with 15-20 days.

Q3.I have no 3D drawing, how should I start the new project?

A :You can provide us a sample, we will help the 3D drawing design.

Q4.Before shipment, how to make sure the products quality?

A : We are in high quality products. We have QC to inspect the products before each shipment. You can come to visit

our factory or ask a third party for inspection. Or we can send you videos to show the production process.

Q5. How could I pay them?

A : Bank transfer,Western Union, T/T, L/C are acceptable, so just let us know which is convenient for you.

Q6.Which Shipment way is available?

A : By sea to your nearest port.

By air to your nearest airport.

By (DHL, UPS, FEDEX, TNT, EMS) to your door.

injection mold factory,injection plastic parts,injection parts for plastic,customized plastic parts.OEM injection parts,low cost mold making injection parts.