injection plastic parts OEM plastic injection mould Factory

|

Mould cavity

|

One cavity, multi-cavity or same different products be made together

|

|||

|

Mould material

|

P20,2738,2344,718,S136,8407,NAK80,SKD61

|

|||

|

Runner system

|

Hot runner and cold runner

|

|||

|

Base material

|

P20,2738,2344,718,S136,8407,NAK80,SKD61

|

|||

|

Finish

|

Pitting the word, mirror finish, matte surface, striae

|

|||

|

Standard

|

HASCO, DME or dependent upon

|

|||

|

Main thechnology

|

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc.

|

|||

|

Software

|

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances)

|

|||

|

Product material

|

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS, TPV, TPO,T PR,EVA,HDPE,LDPE,CPVC,PVDF.

|

|||

|

Quality system

|

ISO9001:2008

|

|||

|

Establish time

|

20days

|

|||

|

Equipment

|

CNC,EDM,Cutting off Machine,plastic machinery,etc

|

|||

Professional manufacturer for injection plastic parts

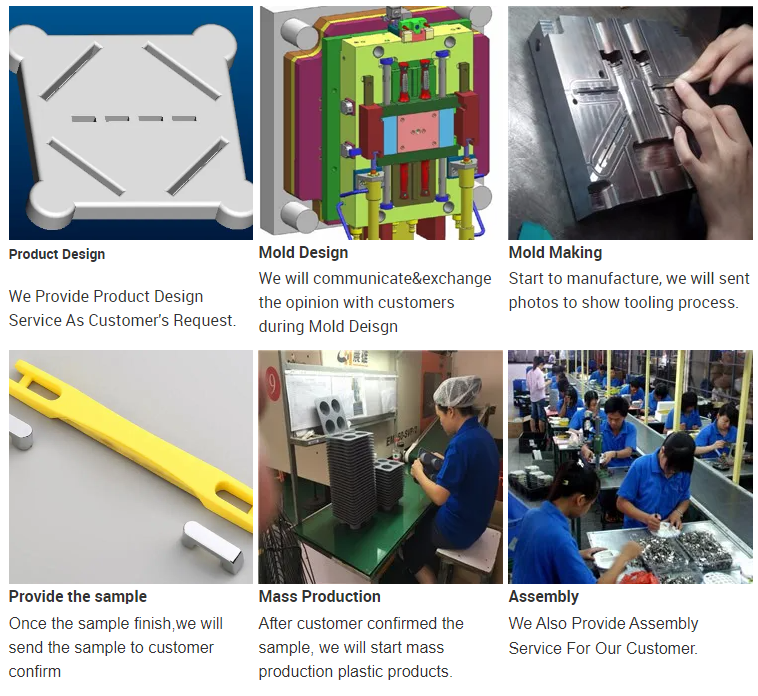

Plastic Injection Mould making:

1.Samples/Drawing &Requirement from you

2.Mould design:we will Communicate and Exchange the opinion with you after you place order.

3.Material Purchase:Steel cutting and Mould base tooling.

4.Assembling.

5.Inspection of mould : following and controlling the tooling processing.

6.Mould testing:We will inform you the date.Than will send the sample's inspection report&injection parameters with the sample to you!

7.Your instruction &confirmation for shipment.

8.Ready made mould before packing.

9.We provide any differeny kinds of plastic injection mould, blow mould, silicone mould, die casting mould service.

Plastic molding Specification:

1. Professional manufacturer,design,production injection mould and stamping mould quality control

2. rich export experience plastic injection mould and stamping mould

3. Reasonable price of design mould

4. Cavities: single or as per your requirements cavity

5. Treatment: S45C Pretreat>25Hrc,And Nitriding

6. Mould Steel: Cavity ,Core and slide: P20 ,2738,2136 available Moldbase :LKM available

7. Standard:DEM ,HUSKY,available

8. Hot runner: according to your demand

9. Life time: >300 Thousand Times

10. Package: Plywood case, anti-rust paint

Factory Tour

Mold Process

Cooperated clients

FAQ:

Q1: Are you trading company or manufacturer ?

A: We are manufacturers.

Q2. When can I get the quotation?

A: We usually quote within 1 days after we get your inquiry.

If you are very urgent, please call us or tell us in your email so that we can quote for you first.

Q3. How long is the lead-time for mold?

A: It all depends on the products' size and complexity. Normally, the lead time is 20-25 days.

Q4. I have no 3D drawing, how should I start the new project?

A: You can supply us a molding sample, we will help you finish the 3D drawing design.

Q5. Before shipment, how to make sure the products quality?

A: If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker.

We will supply you a video for production process detail include process report, products size structure and surface detail, packing detail and so on.

Q6. What is your payment terms?

A: Mold Payment: 40% deposit by T/T in advance, 30% second mold payment before sending out the first trial samples, 30% mold balance after you agree the final samples.

B:Production Payment: 50% deposit in advance, 50% before sending out the final goods.

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit for best quality products .

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

injection mold, Injection Molding Parts, injection molding plastic parts, injection molding of plastic, injection molding plastic ,injection molding plastic products ,injection plastic molding, injection plastic molding companies, injection plastic molding process, mold making for plastic injection