OEM Plastic Injection Parts Customized Small Plastic Parts Molding Service Factory

| Item | High precision plastic injection parts |

|

Color |

White,black,blue,yellow,custom etc |

| Material | ABS,PMMA,PC,PP,PEEK,PU,PA,PA+GF,POM,PE,UPE,PTFE,etc |

| Mould cavity | Single cavity & multi cavity |

| Runner system | hot runner and cold runner |

| Equipment | CNC, EDM, cutting off machine,plastic machinery etc |

| Mould material | P20/ 718H/ S136H/ S136 hardened/ NAK80 |

| Injection machine | 80T-1200T |

| Mould life | 300000-5000000 shots as per customers' requirement |

| Size | customized |

| Tolerance | ± 0.01mm |

| Shape | as per your drawing or the sample |

| Free sample | available |

| Advantage | one stop solution/free design |

| Application field | Electronic products,beauty products,medical products,Auto products,etc |

| Lead ti me | 3-5 days for mould,1-2weeks for plastic products according to quantity |

| Other | 24/7 customer service |

| confidentiality agreement can be signed for project we talked | |

| provides a solution from design to finished products |

FAQs:

1. Why should I entrust my project to you?

Zhongda has 10 years of expertise in mold design, mold build, composite injection molding, and value add services. We clearly know what your product requirements as our rich experience.

2. How to do custom project?

Pls show us for your items design via stp/x/t&prt if you have,we will also help to do FREE design if you dont have.

3. How do you control your quality?

We have a complete set of testing procedures, and quality engineers run various tests in combination with the EPR+MES system, including incoming inspection, in-process inspection, warehousing inspection and a series of tests to ensure quality.

4. What is your lead time?

Plastic Mould time: 15-20days

Plastic parts time: 7-15days based on quality you placed.

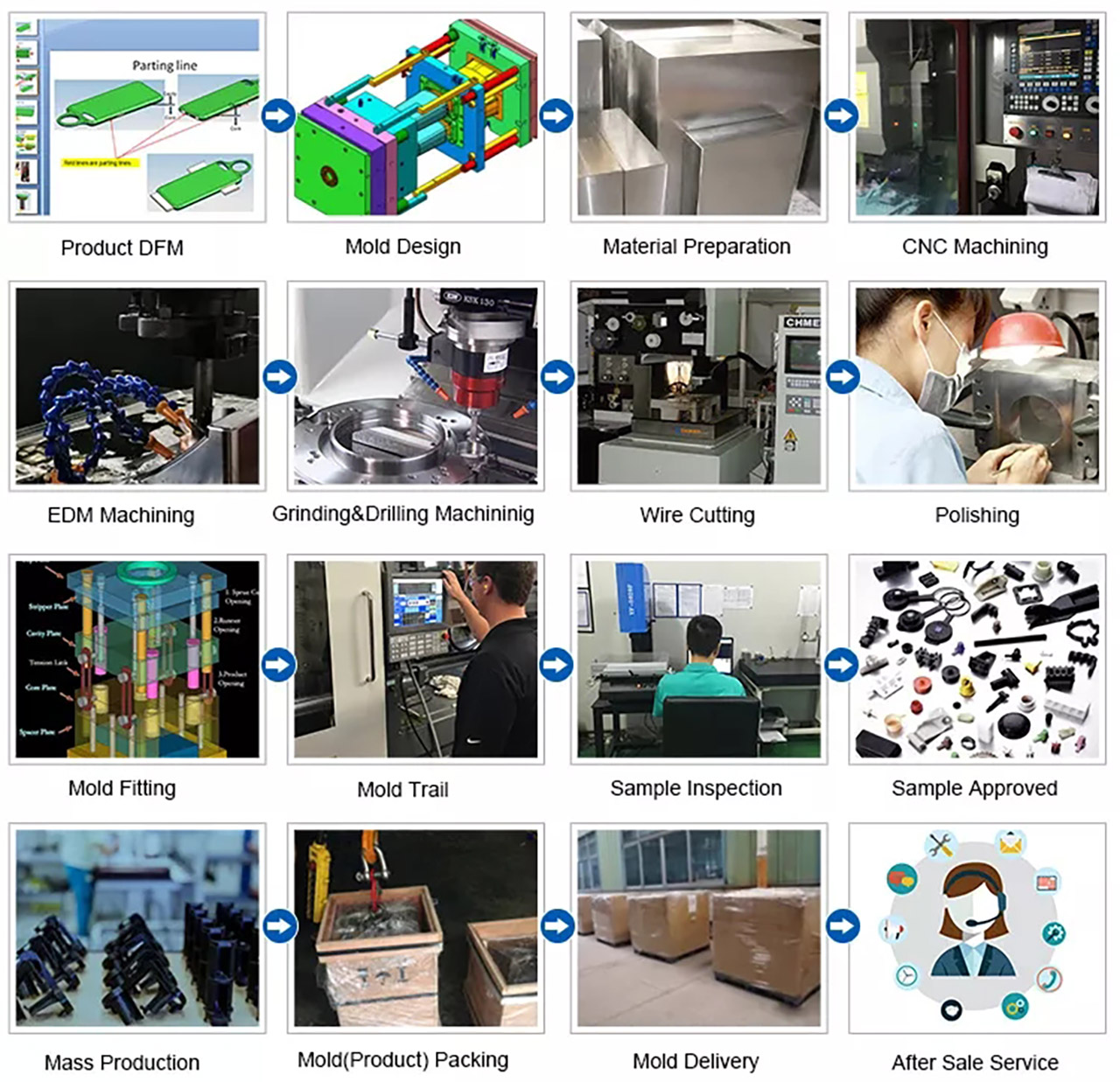

5. What’s the process of custom molding?

a. Customers send inquiry ( drawings or samples);

b. We send quotation sheet;

c. We both make a deal. Customers send the money of toolings;

d. Once getting the deposit of toolings, we start to build the toolings;

e. We produce toolings and samples, then send samples to customers for approval;

f. Once customers approved the samples, we can go ahead with the mass production;

6. What’s the owner of the toolings?

Once customers paid 100% amount of toolings, customers will be the owner of the toolings. We can not produce products by ourselves to sell to other customers.

7. How do you make our business long-term and good relationship?

We keep good quality and competitive price to ensure our customers benefit;

We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.